Features

- The ability to insert and append lines in Special Function windows without scrolling.

- The ability to display new modules in the Profibus Configurator window without scrolling.

Features

Features

Solutions

Solutions

Features

Solutions

Solutions

Solutions

Solutions

Solutions

Solutions

Solutions

Solutions

Features

The software key programming utility used to program FasTrak hardware keys has been changed to program expiration dates into the indefinite future. The following new software versions have been released to support this change.

FasTrak Hardware Key

When inserted into a computer’s USB port, a FasTrak hardware key enables the full functionality of the software. The key has been programmed with an expiration date that corresponds to a customer’s warranty or maintenance agreement period. When a maintenance agreement is renewed, the key is reprogrammed with the corresponding expiration date. Software will continue to run after a key has expired. However an expired key cannot be used with a newer version of the software. FasTrak recommends that customers update their keys each time they renew their maintenance agreements so that they can take advantage of any new features as they are added.

FasTrak Site License

Some customers use keyless site license files instead of hardware keys. The site license file enables the full functionality of the software. Some customers use installation keys to install FasTrak software products and site license files; the installation key is not used to run a software product. This type of site license is referred to as a key-on-install site license. The following information does not apply to customers with keyless or key-on-install site licenses.

Software Upgrade Required to Update FasTrak Hardware Key Beyond 2021

In order to update FasTrak hardware keys with expiration dates beyond 2021, customers will first need to upgrade to the software versions listed above (or subsequent versions) on all computers that are used to run the software.

Note: For users of PLC WorkShop for Siemens 505 V4.70 and earlier, upgrading will introduce a file format change that was made in V4.80 released on 7/31/2014. Program files created or saved by Version 5.11 and higher will not be accessible by V4.70 and earlier WorkShop versions. V5.11 WILL accept program files created in all earlier versions of WorkShop.

Note: For users of PLC WorkShop for Modicon V5.49 and earlier, upgrading will introduce a file format change that was made in V4.50 released on 12/16/2005. Program files created or saved by Version 5.81 and higher will not be accessible by V5.49 and earlier WorkShop versions. V5.81 WILL accept program files created in all earlier versions of WorkShop.

Customers Who Do Not Wish to Upgrade Software Versions

Customers who do not wish to upgrade to these new software versions will be able to continue running older software versions. When running the software with a key that has gone out of date, a message will display indicating that the key has expired. After the message is cleared, the software will continue to run as normal. Customers covered by active maintenance agreements, but with keys that have expired, will be able to upgrade to a later software version at any time by contacting FasTrak’s Technical Support team at 262.238.8088, Option 3 or by email.

Please contact Technical Support at 262.238.8088, Option 3 or by email if you have any questions about upgrading your software or updating your FasTrak hardware key.

Solutions

Solutions

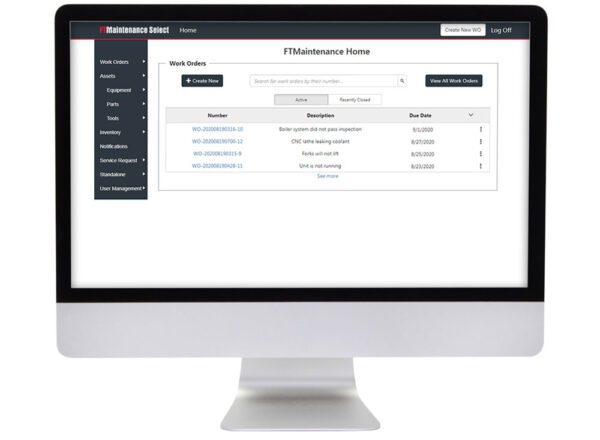

Today, FasTrak SoftWorks, Inc. has officially released FTMaintenance Select – an all-new computerized maintenance management system (CMMS) solution – designed for modern industrial maintenance professionals who require real-time access to their maintenance data. FTMaintenance Select delivers a powerful suite of features for managing work orders, equipment and facility assets, MRO inventory, preventive maintenance, and other maintenance resources.

Cloud-based FTMaintenance Select will allow teams to access their maintenance data from any internet-connected device. Speaking about the benefits FTMaintenance Select will provide to customers, FTMaintenance Product Expert Dave Dulak said, “The FTMaintenance Select platform has been designed to be future-proof for our clients.”

Industrial automation is essential to meeting the challenges, and leveraging the opportunities, of global urbanization. For over 30 years, FasTrak has been helping organizations across the world better serve their communities and markets with software products for PLC programming, file change management, and maintenance management.

The introduction of FTMaintenance Select demonstrates a deep commitment to helping organizations improve maintenance operations, reduce asset and facility downtime, and continuously improve products, services, and processes. “FTMaintenance Select is going to address the needs of industrial companies, organizations involved with facility management, companies that manage distributed assets, and third-party maintenance providers,” says Dulak. Industries served by FTMaintenance Select include manufacturing, facility and property management, food and beverage, government, healthcare, oil and gas, pharmaceuticals, power and energy, water, and many others.

This new product launch is driven by the following market factors:

FasTrak believes FTMaintenance Select is well-positioned to meet the needs of an evolving maintenance management market. “FTMaintenance Select is uniquely built to easily change and adapt to the ever-changing requirements of customers, which protects their investment into the future,” says Enterprise Architecture Manager Mohamed Elbendary.

FTMaintenance Select is more than just a powerful CMMS product – it’s an entire software platform that will allow organizations to easily scale their maintenance operations as their business grows. This platform enables FTMaintenance Select to expand through connections to other business and productivity applications. “FTMaintenance Select integration connectors enable customers to automate workflows and share data with other departments and organizations, such as customers or business partners,” says Elbendary.

FTMaintenance Select CMMS will be expanded with companion mobile applications, making it a perfect fit for today’s highly-mobile maintenance teams. Organizations with advanced maintenance operations will be able to extend FTMaintenance Select with an Application Programming Interface (API), enabling the flow of critical information between FTMaintenance Select and other applications including:

FTMaintenance Select is a feature-rich, easy-to-use maintenance management solution delivered on a flexible, web-based platform. FTMaintenance Select is designed to rapidly evolve, adding new features and functionality, performance enhancements, and other improvements. Users automatically receive all product updates. Contact us to learn more about FTMaintenance Select.

Features

Solutions

Solutions

Features

Solutions

FTSolution for APT is a Microsoft Windows-based direct replacement for Siemens-obsoleted DOS APT software designed to extend the life of Siemens and CTI 2500 Series PLCs and APT programs. Demonstrating our commitment to preserving your investment in APT language systems, FasTrak SoftWorks, Inc. is pleased to announce the release of FTSolution for APT V2.2.3, which incorporates:

Purchase FTSolution for APT to take full advantage of this, and future, enhancements. Purchase includes a warranty offering 12 months of free updates and technical support.

Solutions

FasTrak SoftWorks, Inc. is pleased to announce the release of FTSolution for APT V2.2.2. FTSolution for APT is a Microsoft Windows-based direct replacement for Siemens-obsoleted DOS APT software designed to extend the life of Siemens and CTI 2500 Series PLCs and APT programs.

Purchase FTSolution for APT to take full advantage of this, and future, enhancements. Purchase includes a warranty offering 12 months of free updates and technical support.

Recent Comments